|

!WARNING

· Use PPTC beyond the maximum ratings or improper use may result in device damage and possible electrical arcing and flame.

· PPTC are intended for protection against occasional over current or over temperature fault conditions and should not be used when repeated

fault conditions or prolonged trip events are anticipated.

· Device performance can be impacted negatively if devices are handled in a manner inconsistent with recommended electronic, thermal, and

mechanical procedures for electronic components.

· Use PPTC with a large inductance in circuit will generate a circuit voltage (L di/dt) above the rated voltage of the PPTC.

· Avoid impact PPTC device its thermal expansion like placed under pressure or installed in limited space.

· Contamination of the PPTC material with certain silicon based oils or some aggressive solvents can adversely impact the performance of the

devices. PPTC SMD can be cleaned by standard methods.

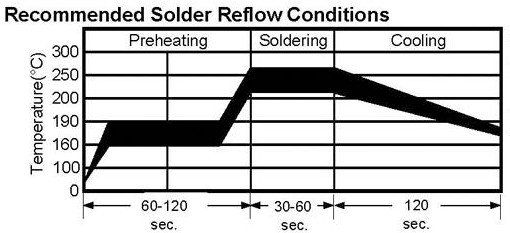

· Requests that customers comply with our recommended solder pad layouts and recommended reflow profile. Improper board layouts or

reflow profile could negatively impact solderability performance of our devices.

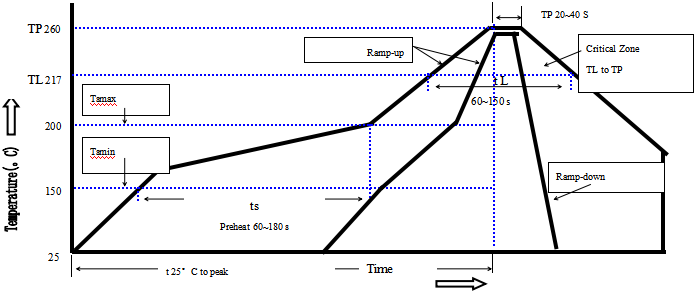

Soldering Parameters

|

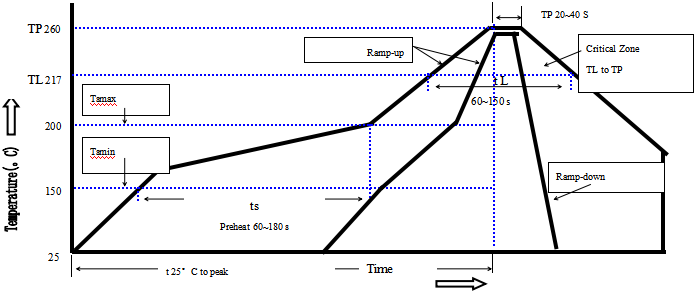

Profile Feature

|

Pb-Free Assembly

|

|

Average Ramp-Up Rate(Ts max to T p)

|

3℃/second mac.

|

|

Preheat

-Temperature Min(Ts min)

-Temperature Max(Ts max)

-Time(Ts min to Ts max)

|

150℃

200℃

60~180 seconds

|

|

Time maintained above:

-Temperature(TL)

-Time(tL)

|

217℃

60~150 seconds

|

|

Peak Temperature(Tp)

|

260℃

|

|

Ramp-Down Rate

|

6℃/second max.

|

|

Time 25℃ to Peak Temperature

|

8 minutes max

|

|

Storage Condition

|

0℃~30℃,30%-60%RH

|

Recommended reflow methods: IR, vapor phase oven, hot air oven, N2 environment for lead-free

Recommended maximum paste thickness is 0.25mm

Devices can be cleaned using standard industry methods and solvents.

Note 1:All temperature refer to topside of the package, measured on the package body surface.

Note 2: If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements.

|