0603(1.6x0.8)-貼片保險(xiǎn)絲

實(shí)物圖片:

Features產(chǎn)品特點(diǎn):

? Compatible with leadfree solders and higher temperature profiles.

? High performance materials provide improved performance in elevated ambient temperature applications.

? Marked on top surface with code to allow amp rating identification without testing.

? Low profile for height sensitive applications.

? Flat top surface for pickand-place operations.

? Element covering material is resistant to industry standard cleaning operations.

Applications產(chǎn)品應(yīng)用:

Secondary protection for space constrained applications:

? Cell phones

? Battery packs

? Digital cameras

? DVD players

? Hard disk drives.

|

Electrical Characteristics for Series

|

|

% of Ampere Rating

|

Opening Time at 25OC

|

|

100%

|

0.25-8A

|

4 hours, Minimum

|

|

200%

|

0.25-6A

|

5 sec., Maximum

|

|

250%

|

7-8A

|

5 sec., Maximum

|

|

300%

|

0.25-8A

|

0.2 sec., Maximum

|

Electrical Specifications by Item

|

AmpereRating

(A)

|

Amp

Code

|

Max

Voltage

Rating(V)

|

Interrupting

Rating

|

Nominal Cold

Resistance

(Ohms)

|

Nominal

Melting

I2t (A2sec)

|

Nom

Voltage

Drop(mV)

|

Nom

Power

Dissipation

(W)

|

Agency Approvals

|

|

UR

|

CSA

|

|

0.250

|

.250

|

125

|

50A @32V AC

50A@63VDC

|

0.5450

|

0.0030

|

158.56

|

0.0396

|

x

|

x

|

|

0.375

|

.375

|

125

|

0.2900

|

0.0053

|

128.03

|

0.0480

|

x

|

x

|

|

0.500

|

.500

|

125

|

0.1870

|

0.0087

|

115.71

|

0.0579

|

x

|

x

|

|

0.750

|

.750

|

125

|

0.1170

|

0.0171

|

107.33

|

0.0805

|

x

|

x

|

|

1.00

|

001.

|

125

|

0.0710

|

0.0212

|

89.10

|

0.0891

|

x

|

x

|

|

1.25

|

1.25

|

125

|

0.0530

|

0.0518

|

84.125

|

0.1054

|

x

|

x

|

|

1.50

|

01.5

|

125

|

0.0410

|

0.0766

|

81.14

|

0.1217

|

x

|

x

|

|

1.75

|

1.75

|

125

|

50A @32V AC/DC

|

0.01250

|

0.0903

|

78.75

|

0.1378

|

x

|

x

|

|

2.00

|

002.

|

125

|

0.0300

|

0.1103

|

78.22

|

0.1564

|

x

|

x

|

|

2.50

|

02.5

|

63

|

0.0220

|

0.1440

|

76.10

|

0.1903

|

x

|

x

|

|

3.00

|

003.

|

63

|

0.0180

|

0.2403

|

75.04

|

0.2251

|

x

|

x

|

|

3.50

|

03.5

|

63

|

0.0150

|

0.4306

|

74.25

|

0.2599

|

x

|

x

|

|

4.00

|

004.

|

63

|

0.0130

|

0.5760

|

73.72

|

0.2949

|

x

|

x

|

|

5.00

|

005.

|

63

|

0.0090

|

0.9000

|

72.71

|

0.3635

|

x

|

x

|

|

6.00

|

006

|

63

|

0.0085

|

1.3838

|

72.00

|

0.432

|

x

|

x

|

|

7.00

|

007

|

63

|

0.0080

|

1.5673

|

68.51

|

0.5123

|

x

|

x

|

|

8.00

|

008

|

63

|

0.0075

|

1.8321

|

65.24

|

0.5945

|

x

|

x

|

1. Measured at 10% of rated current, 25oC. 2. Measured at rated voltage.

Temperature Rerating Curve

Note:

1. Derating depicted in this curve is in addition to the standard derating of 25% for

continuous operation.

Example:For continuous operation at 70 degrees celsius, the fuse should be deratedas follows:

I = (0.75)(0.80)IRAT = (0.60)IRAT

2. The temperature derating curve represents the nominal conditions. For questions about temperature derating curve,

please consult our technical support for assistance.

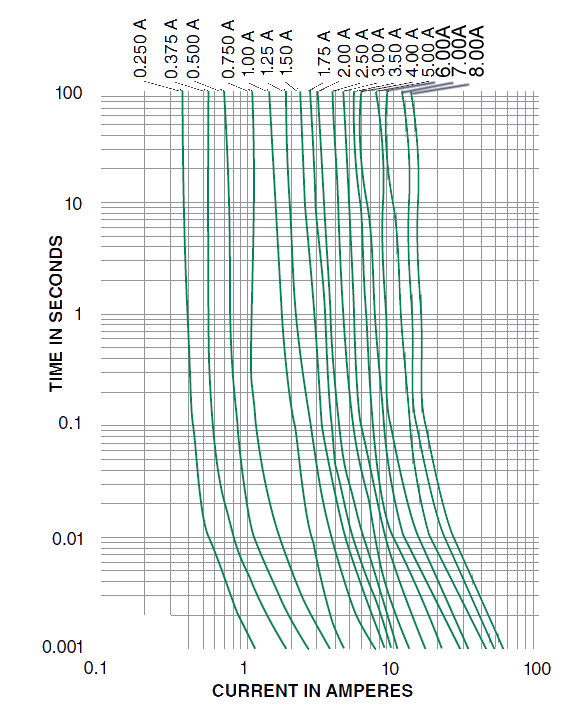

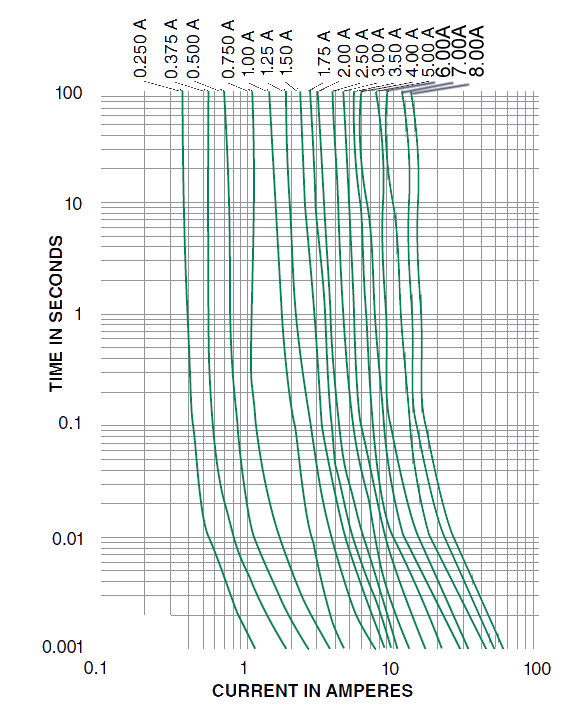

Average Time Current Curves

Soldering Parameters

|

Reflow Condition

|

Pb– Free assembly

|

|

Pre Heat

|

Temperature Min (Ts(min))

|

150°C

|

|

Temperature Max (Ts(max))

|

200°C

|

|

Time (Min to Max) (ts)

|

60 – 180 secs

|

|

Average ramp up rate (Liquidus Temp(TL) to peak

|

5°C/second max

|

|

TS(max) to TL-Ramp-up Rate

|

5°C/second max

|

|

Reflow

|

Temperature (TL) (Liquidus)

|

217°C

|

|

Temperature (tL)

|

60 – 150 seconds

|

|

Peak Temperature (TP)

|

250+0/-5 °C

|

|

Time within 5°C of actual peak Temperature (tp)

|

20 – 40 seconds

|

|

Ramp-down Rate

|

5°C/second max

|

|

Time 25°C to peak Temperature (TP)

|

8 minutes Max.

|

|

Do not exceed

|

260°C

|

|

Wave Soldering

|

260°C, 10 seconds max.

|

Product Characteristics

|

Materials

|

Body: Advanced High Temperature Substrate

|

|

Terminations: 100% Tin over Nickel over Copper

|

|

Element Cover Coat: Conformal Coating

|

|

Operating Temperature

|

– 55OC to 90OC. Consult temperature rerating curve chart. For operation above 90°C contact us

|

|

Humidity

|

MIL-STD-202F, Method 103B, Condition D

|

|

Thermal Shock

|

Withstands 5 cycles of – 55OC to 125OC

|

|

Vibration

|

Per MIL-STD-202F

|

|

Insulation Resistance (After Opening)

|

Greater than 10,000 ohms.

|

|

Resistance to Soldering Heat

|

MIL-STD-202G, Method 210F,Condition D

|

Dimensions

Dimensions

|

|

|

|

Part Marking System

|

|

Amp Code

|

Marking Code

|

|

.250

|

D

|

|

.375

|

E

|

|

.500

|

F

|

|

.750

|

G

|

|

001.

|

B

|

|

1.25

|

J

|

|

01.5

|

H

|

|

1.75

|

L

|

|

002.

|

K

|

|

02.5

|

L

|

|

003.

|

O

|

|

03.5

|

R

|

|

004.

|

S

|

|

005.

|

T

|

|

006

|

U

|

|

007

|

V

|

|

008

|

W

|

|

東莞市富寬源電子有限公司(東莞市富源電子科技有限公司)成立于1998年�,主要從事安規(guī)元器件生產(chǎn)和銷售�,通過10年的改革和努力現(xiàn)在的富寬源已經(jīng)成為集生產(chǎn)和銷售為一體的安規(guī)元器件總匯����;富寬源將繼續(xù)秉持品質(zhì)第一、服務(wù)客戶的原則不斷為廣大客戶提供質(zhì)優(yōu)價(jià)廉的產(chǎn)品�。我公司目前主要提供如下產(chǎn)品:

電流保險(xiǎn)絲-CurrentFuse

玻璃管電流保險(xiǎn)絲

陶瓷管電流保險(xiǎn)絲

貼片電流保險(xiǎn)絲

電阻式保險(xiǎn)絲

微型電流保險(xiǎn)絲

高壓電流保險(xiǎn)絲

直流電流保險(xiǎn)絲

交流電流保險(xiǎn)絲

SMD-貼片式自恢復(fù)保險(xiǎn)絲

AI-插件式自恢復(fù)保險(xiǎn)絲

保險(xiǎn)絲座-Fuseholder

ESTMF系列保險(xiǎn)絲座

EDKFH系列保險(xiǎn)絲座

SKPTF系列保險(xiǎn)絲座

AUTO--汽車保險(xiǎn)絲座

OPWOP系列保險(xiǎn)絲座

拉線盒式保險(xiǎn)絲座

保險(xiǎn)絲夾&端子

保險(xiǎn)管座

保險(xiǎn)座

大電流|高壓保險(xiǎn)座

溫度保險(xiǎn)絲-Thermalcutoffs

方塊形溫度保險(xiǎn)絲

電阻式溫度保險(xiǎn)絲

大電流溫度保險(xiǎn)絲

陶瓷溫度保險(xiǎn)絲

鐵殼溫度保險(xiǎn)絲

SW.C溫度保險(xiǎn)絲

NEC溫度保險(xiǎn)絲

艾默生溫度保險(xiǎn)絲

內(nèi)橋溫度保險(xiǎn)絲

松下溫度保險(xiǎn)絲

AUPO溫度保險(xiǎn)絲

溫度開關(guān)/溫控器-Thermalprotector

熱保護(hù)器/可恢復(fù)溫控器

風(fēng)筒式溫控開關(guān)/溫控器

馬達(dá)熱保護(hù)器/溫控器

除霜除濕溫控器/溫控開關(guān)

超低溫溫控開關(guān)/溫控器

微型溫控開關(guān)/溫控器

溫度開關(guān)/溫控器-Thermalprotector

7AM/17AM溫控器

KSD301系列溫開關(guān)

KSD-01F插腳溫開關(guān)

9700系列方塊形溫控開關(guān)

BR系列溫控開關(guān)

SEKIST-22溫控器

壓敏電阻-Varistors

壓敏電阻

氧化鋅壓敏阻器

貼片壓敏電阻

SMD壓敏電阻

插件型壓敏電阻

高能壓敏電阻

汽車保險(xiǎn)絲Autofuse/carfuse

小號汽車插片保險(xiǎn)絲FY-MIN

中號汽車插片保險(xiǎn)絲FY-ATC

大號汽車插片保險(xiǎn)絲FY-MAX

小號叉栓式汽車保險(xiǎn)絲FY-UF

大號汽車叉栓式保險(xiǎn)絲FY-MF

管狀|柱狀汽車保險(xiǎn)絲

其他型號汽車保險(xiǎn)絲

過載保護(hù)器-CIRCUITBREAKER

AR1/AR2系列過載保護(hù)器

W系列過載保護(hù)器

88/88A系列過載保護(hù)器

90系列過載保護(hù)器

91/91L系列過載保護(hù)器

97/98/98H系列過載保護(hù)器

帶開關(guān)系列過載保護(hù)器

熱敏電阻-NTC/PTCThermistor

負(fù)溫度系數(shù)熱敏電阻

陶瓷正溫度系數(shù)熱敏電阻

高分子正溫度系數(shù)熱敏電阻

溫度傳感器

濕度傳感器

本公司將繼續(xù)通過ISO9000質(zhì)量管理體系的有效實(shí)施��,使涉及企業(yè)生產(chǎn)經(jīng)營的各個(gè)運(yùn)作環(huán)節(jié),均嚴(yán)謹(jǐn)有序����,不斷制造出質(zhì)優(yōu)價(jià)廉��、適銷對路的產(chǎn)品參與市場競爭����,使企業(yè)長期保持較強(qiáng)的經(jīng)營獲利能力。同時(shí)我們將長期重視與行業(yè)知名企業(yè)合作���,爭取最大限度的代理權(quán),以最優(yōu)惠的價(jià)錢把產(chǎn)品銷售給客戶���。